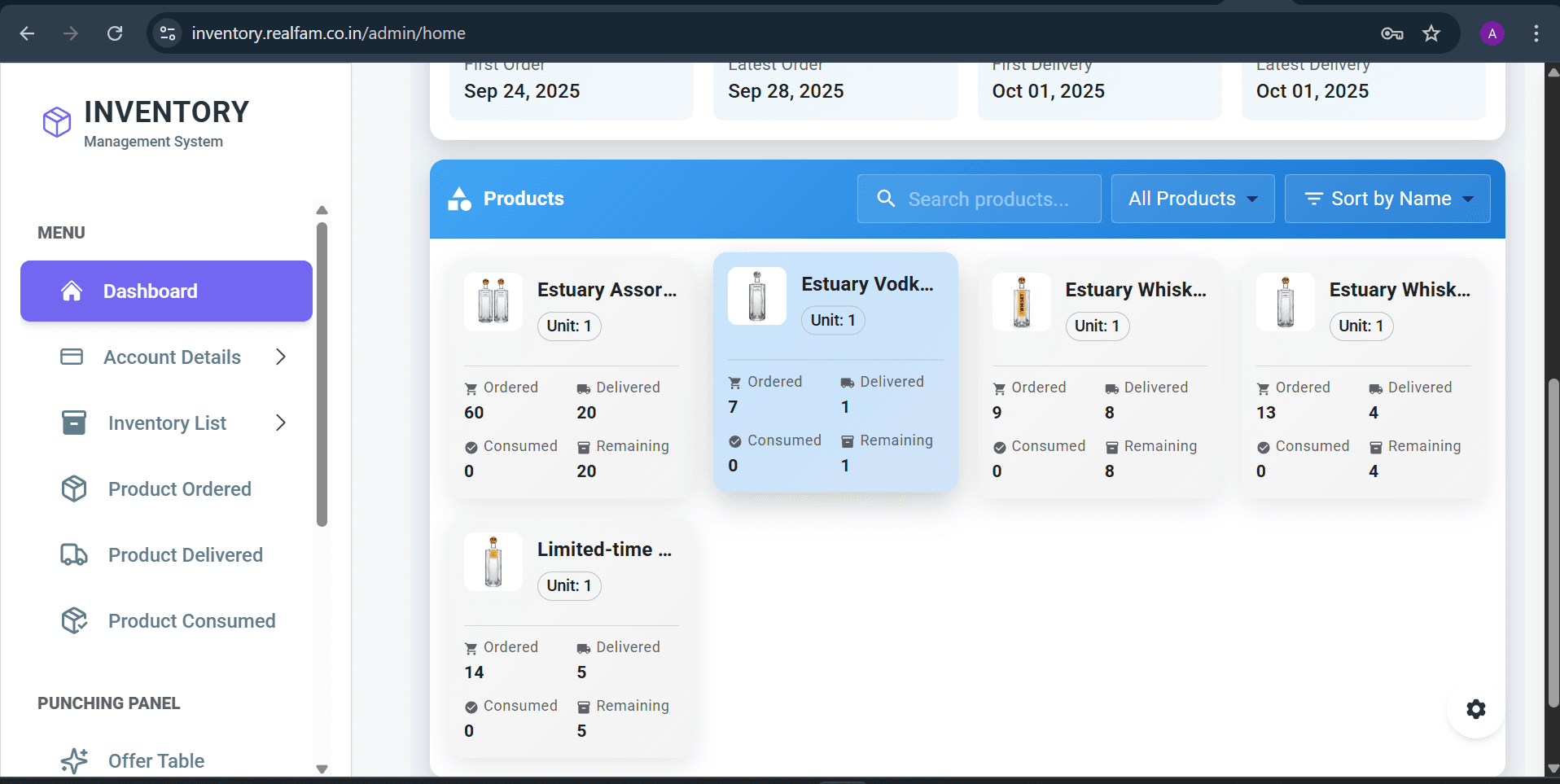

A comprehensive guide to building an inventory management system with automatic order assignment, real-time stock tracking, and role-based dashboards.

The Challenge

A growing e-commerce business was struggling with manual inventory tracking across multiple warehouses. Stock discrepancies were common, and order fulfillment was slow.

System Design

I built a comprehensive inventory management system with these core features:

Real-Time Stock Tracking

- Automatic updates when orders are placed or fulfilled

- Low stock alerts with configurable thresholds

- Multi-warehouse inventory visibility

- SKU-level tracking with batch numbers

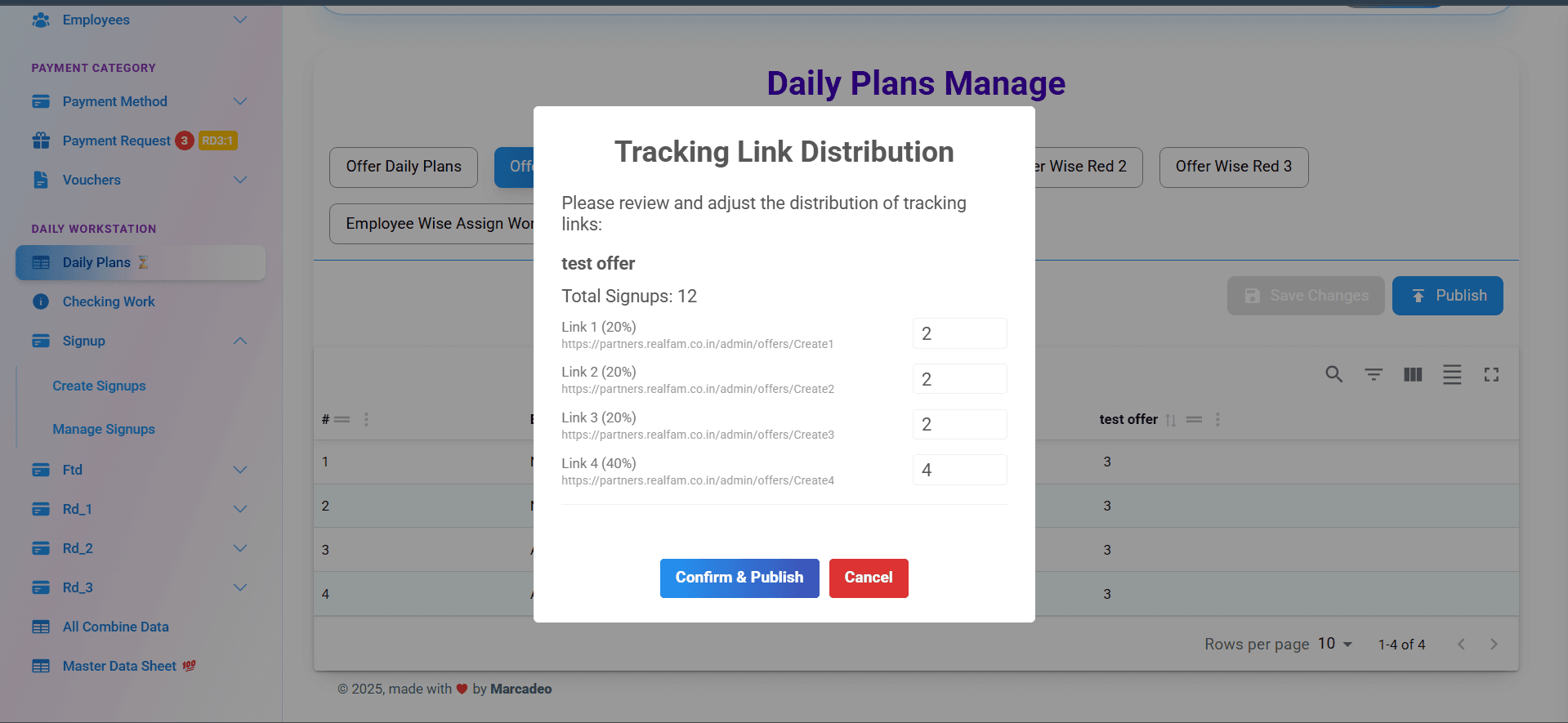

Automatic Order Assignment

Smart algorithm that assigns orders based on:

- Stock availability at nearest warehouse

- Shipping cost optimization

- Warehouse capacity and workload

- Priority order handling

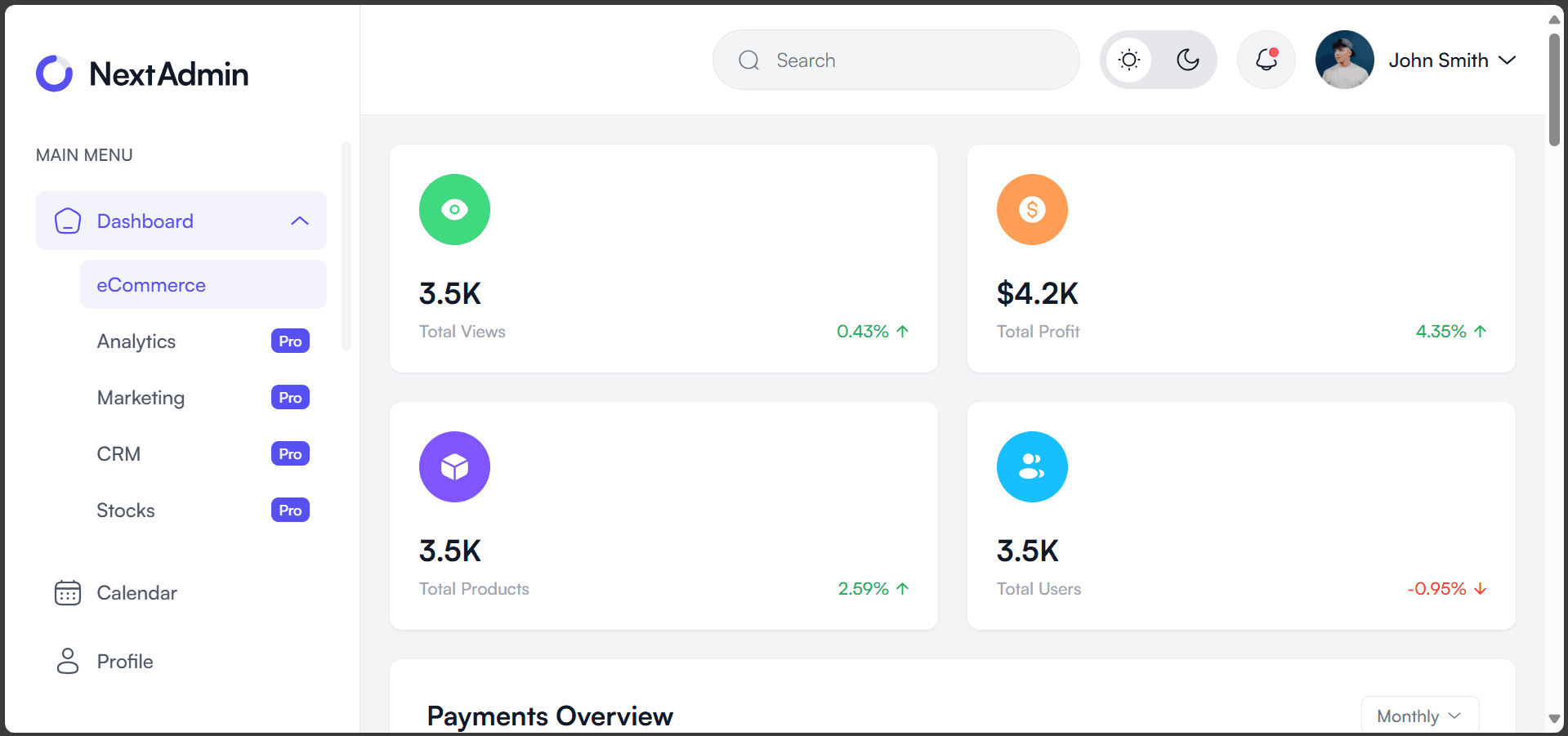

Technical Stack

Built with MERN stack featuring:

- MongoDB: Flexible schema for product variants

- Express/Node.js: RESTful API with real-time updates

- React: Responsive dashboards for different roles

- Redis: Caching for frequently accessed inventory data

Key Features

Role-Based Dashboards

Warehouse Managers: Stock levels, order queue, fulfillment metrics

Purchasing Team: Reorder alerts, supplier management, cost tracking

Operations: Order status, shipping coordination, exception handling

Automation Features

- Automatic purchase orders when stock reaches reorder point

- Smart vendor selection based on price and delivery time

- Predictive stock alerts using historical data

- Barcode scanning integration for quick updates

Performance Optimizations

To handle high transaction volumes:

- Implemented optimistic UI updates

- Database indexing on frequently queried fields

- Batch processing for bulk updates

- CDN for product images

Results

- 80% reduction in manual tracking time

- 95% inventory accuracy (up from 78%)

- 30% faster order fulfillment

- Zero stockouts in 6 months

Lessons Learned

Real-time systems need careful consideration of data consistency. We used optimistic locking to prevent race conditions. The key to adoption was making the interface intuitive for warehouse staff who weren't tech-savvy.